ES 100 Portable Busbar Bending and Punching Machine 10x100mm

ES 100 machine process copper busbars up to 10x100 mm. It has options of settings by hand switch on punching process. You may lift busbar up and make smooth punching from bottom due to fly wheel in side of machine. Machine is portable to provide easier and better operation facilities to the customers.

Technical Specifications |

ES100 |

|||

|

Mechanic Information |

Punching-Bending |

Maximum Capacity |

mm |

10x100 |

|

Punching |

Minimum – Maximum Diamater |

mm |

Ø6~18 |

|

|

Bending |

Bending Range in Degrees |

mm |

80°-150° |

|

|

|

Width x Length x Height |

cm |

50x90x45 |

|

|

Space |

m³ |

0.21 |

||

|

Total Weight |

kg |

80 |

||

Standard Tools |

|

Punching Tool |

|

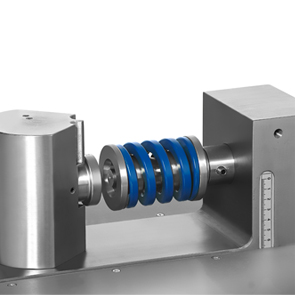

Wide Bending Tool R10 |

|

Wide Bending Tool Die R10 |

|

Length stop |

|

Hand control |

|

|

|

|

HU 350 Portable Electric Hydraulic Unit

.jpg) |

|

||||||||||||||||||||||||||||||||||||||||||||||||||